Fluid Filtration

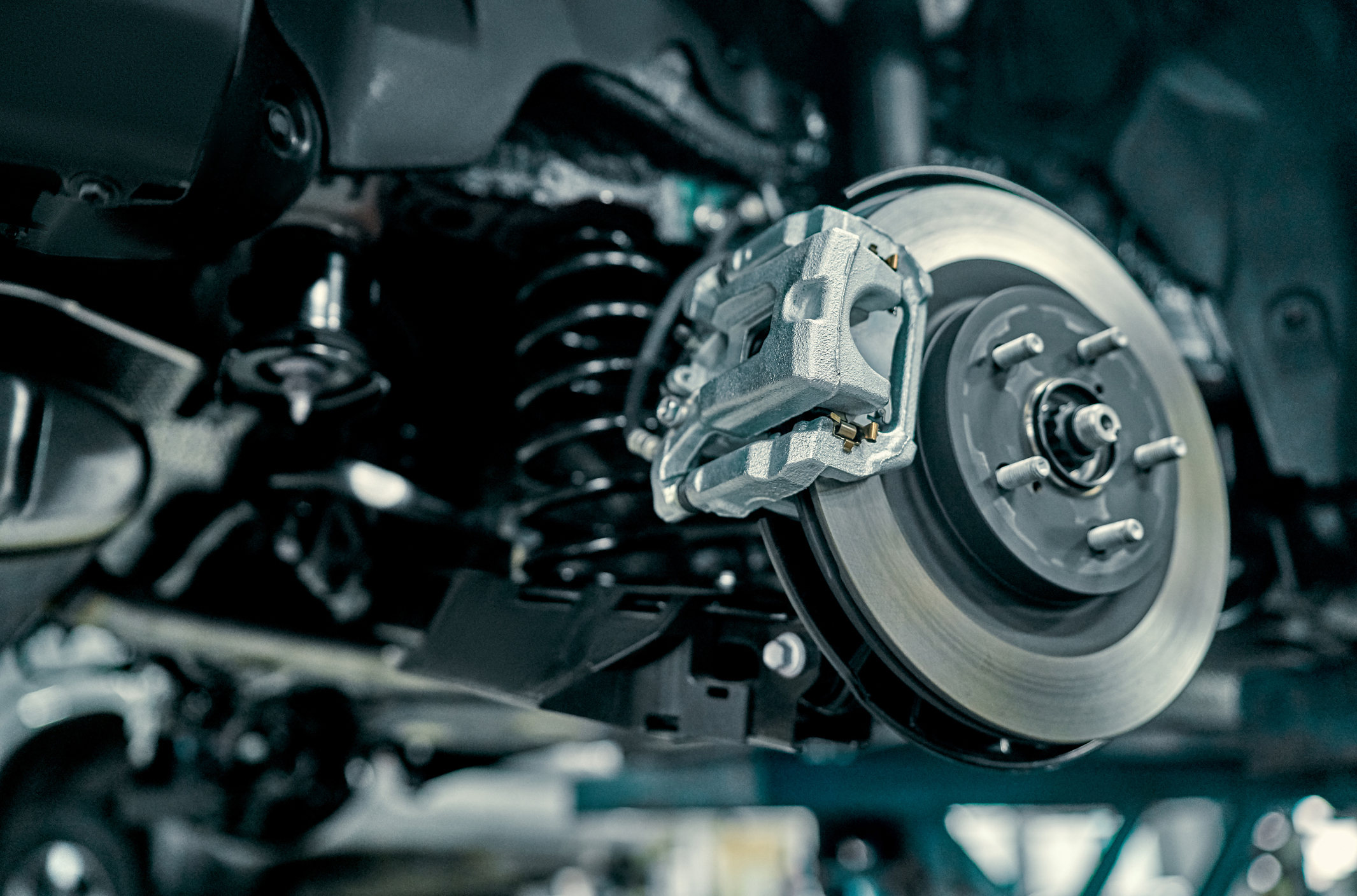

Modern vehicles use a range of fluids which require filtration, either for reliable operation of circuits or when filling up. These include fuels, brake fluid, engine oil, AdBlue/urea and many more.

Generally, mini filters or clip filters are used to filter these fluids. The filter consists of a plastic frame, which defines its geometry. Our meshes are set into this frame using injection moulding techniques.

Most use thermally treated and calendered meshes. The DKS process developed by BOPP means wires coming into contact within the mesh are effectively ‘welded’ together to prevent any wires coming loose. Particularly after the bands of mesh are cut to widths from 3.75mm, sintering prevents wires on the cut edges from coming loose. This assures safe automated processing for injection moulding machines.

Using a combination of rolling and calendering, the mesh is flattened to its final dimensions. The thickness of the mesh can be calibrated to within just a few microns, so a mould gap produced to this measurement ensures no spare matter gets into the filter during the injection moulding process.

- The variety of applications in vehicles demands the most diverse range of meshes

- In-house developed DKS processes safeguard against loose wires

Download PDF 9.6 MB

Products

Below you will find the products typically used for this application. We will be happy to help you select the most suitable specification for your needs. Please contact us.

Product search according to properties

Search for suitable products for already concrete requirements of our metal mesh.

Product search according to properties

Search for suitable products for already concrete requirements of our metal mesh.