Fabrication

Pickling and passivating

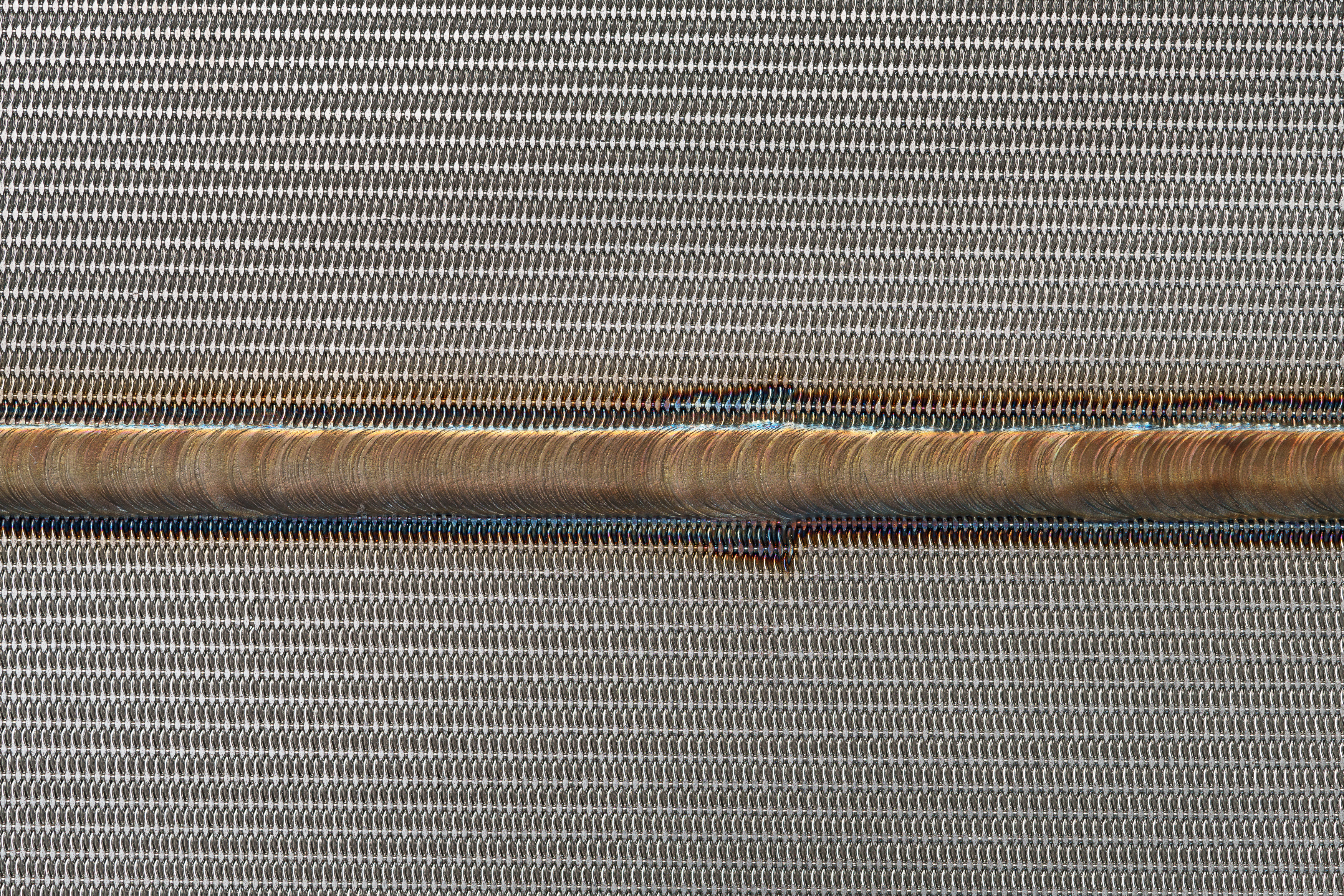

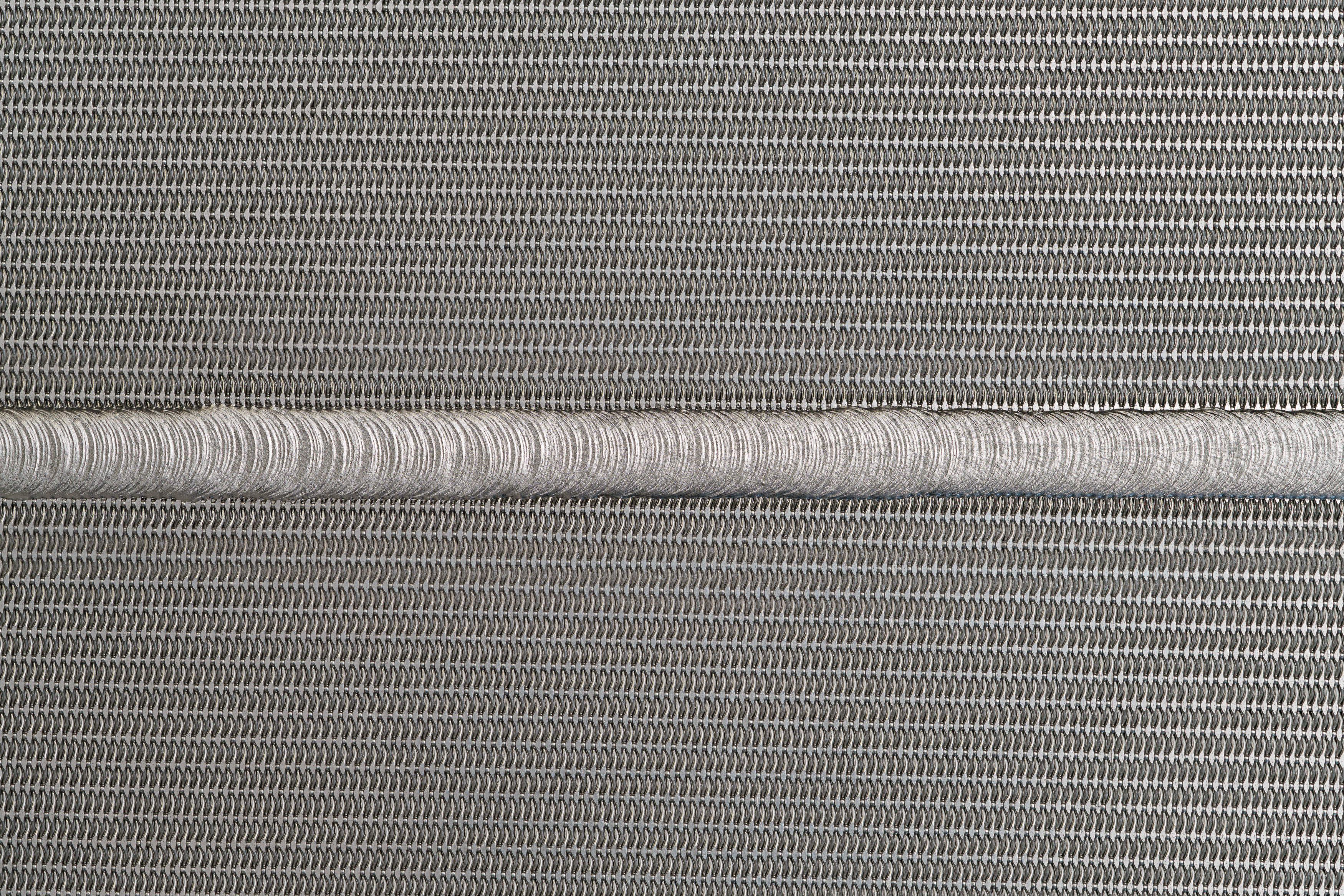

Any additional processing of our steel meshes, for example laser cutting, grinding or welding, can destroy the naturally passive layer of the steel surface. Dependent on the properties of the material, this can sooner or later lead to corrosion.

To avoid the process of corrosion, pickling and passivating provide vital steps in the further processing of our stainless steel meshes.

The pickling process eliminates impurities and removes oxides, for example annealing coloration from welding. Subsequently, passivating creates a new, intact and uniform layer on the surface. The mesh is thereby given optimal protection against environmental impact, even in harsh operating conditions.

These processes enable us to guarantee our products meet the most demanding requirements in terms of cleanliness and resistance to corrosion. Our portfolio includes:

- Discs or filter floors up to 3m in diameter

- Filter candles or pleated filters up to 800mm in diameter and 2m in length

- All products manufactured using stainless steel

Here for you.

How can we help you?